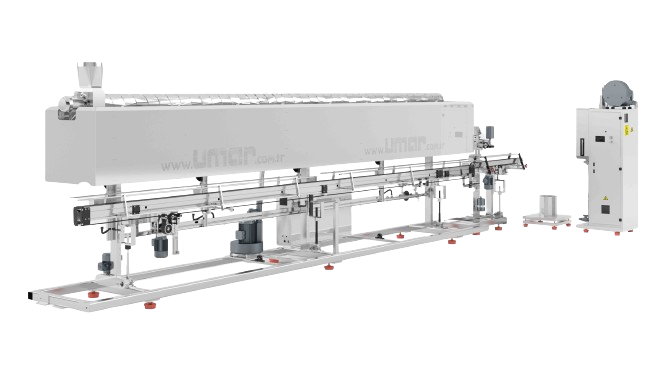

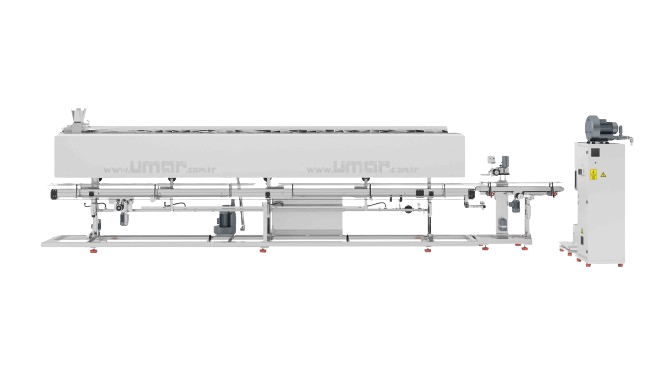

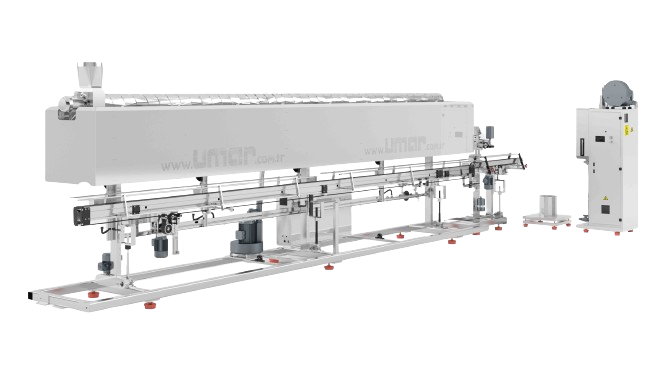

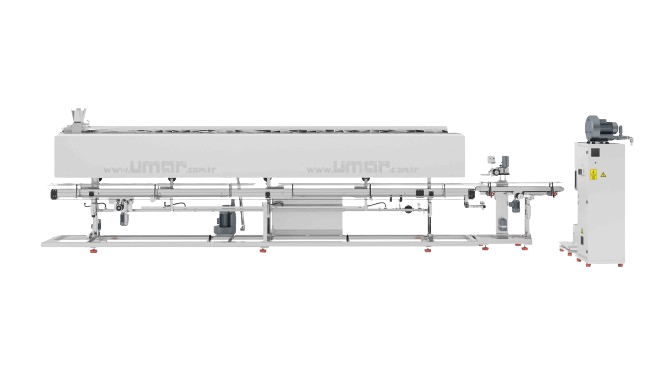

Seam Protection & Curing System

Seam Protection & Curing System

For Internal & External Weld Line Protection of Three-Piece Cans

The UMAR Seam Protection and Curing System is engineered to provide reliable and effective protection for the welded seam of three-piece cans, ensuring long-term durability, corrosion resistance, and food safety.

This compact, high-performance unit can be seamlessly integrated after any brand of Can Body Welder and is compatible with a variety of production line configurations.

This system is commonly installed directly after the welding machine and before downstream processing to protect the can seam prior to further finishing (e.g., powder coating or labeling). Especially important for food-grade cans, where durability and contamination prevention are critical.

| Feature | Specification |

|---|---|

| Heating Type | Electric Induction (Standard) LPG / Natural Gas (Optional) |

| Heating Heads | 2 pcs, straight, gradual heat |

| Total Heating Length | 3 meters |

| Can Diameter Range | Ø70 – Ø300 mm |

| Can Transport | Single belt with magnetic rails |

| Speed Control | Adjustable conveyor speed |

| Control System | PLC |

Fill out our form to get more detailed information about our products. We will get back to you as soon as possible during our business hours. By learning more about our products, we will help you choose the option that best suits your needs.

Umar Bildirim Merkezi

Umar Bildirim Merkezi