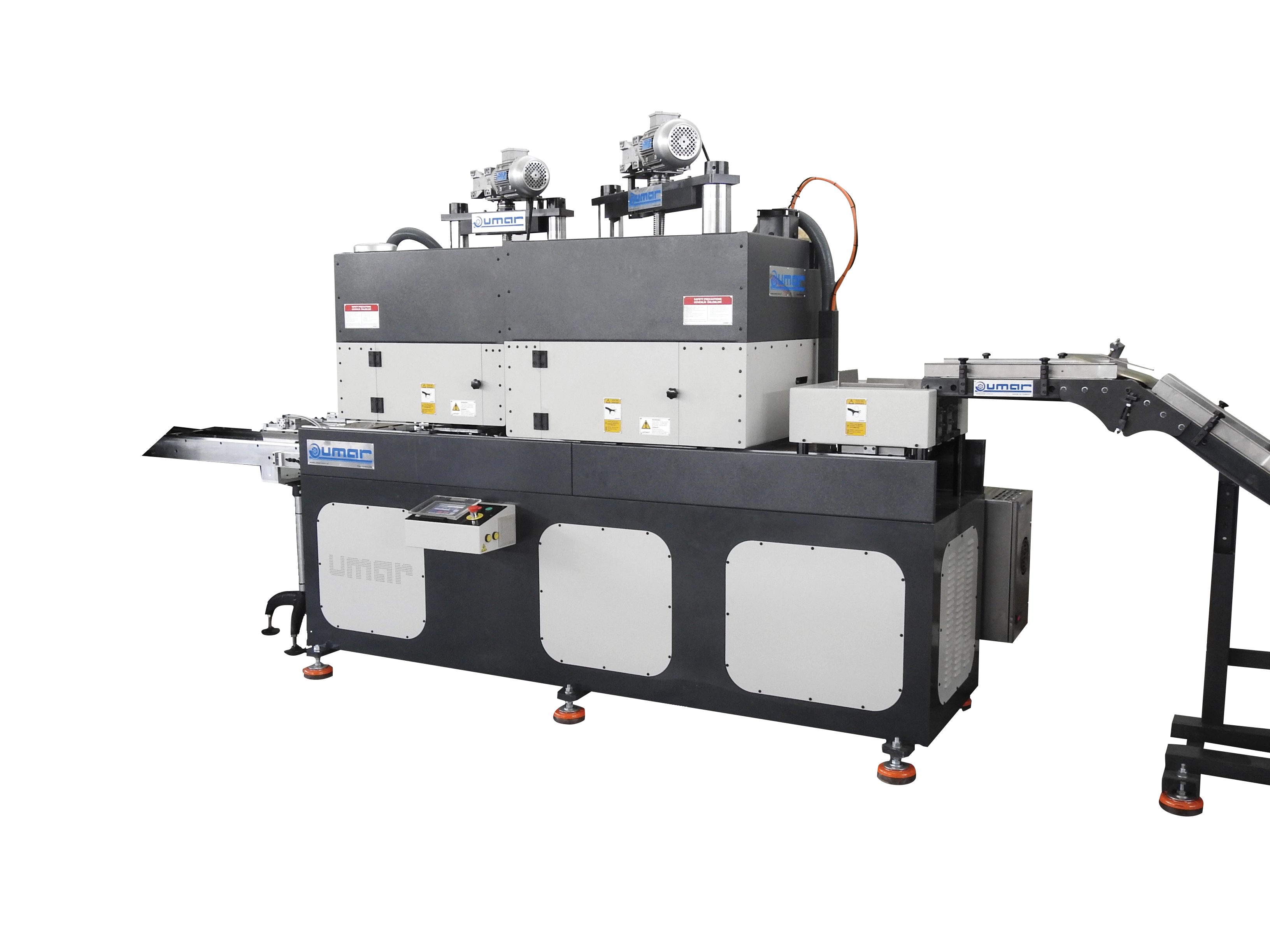

MAC/61742 Angular End Curling and Lining Machine

The curled edge and lined ends, lids are manufactured automatically in this machine.

Machine consists of three stations:

1st Station: De-stacker of flat edge ends.

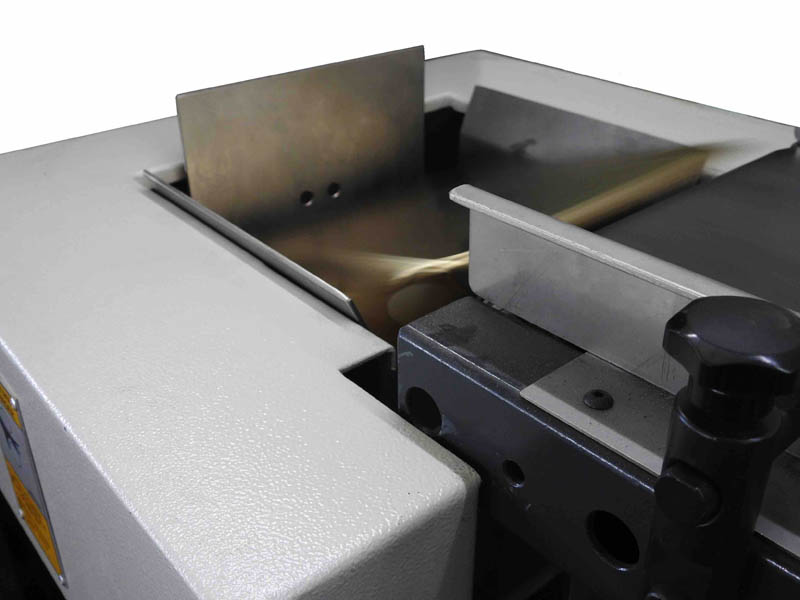

2nd Station: Curling: Curling of flat edge ends to full curled ends by roller system. The curling operation is done with curling head which has four curling rollers running around the end edge following a cam system.

3rd Station: Lining: The sealing compound is lined into curled edges of the ends by double nozzle system.

-

Curling or/and lining stations. (optional)

-

Automation system with servo motion control.

-

Easy maintenance and practical adjustment.

-

90 lt compound tank with mixer.

-

On the exit tool to vertical oven for drying or stacking of ends in groups.

| Capacity | 60 - 80 ends/minute |

| End Dimension Range | 80x80 mm - 235x235 mm |

| Total Power | 2o kW |

Show More